MetalForming Offers

New Tech Rollformers

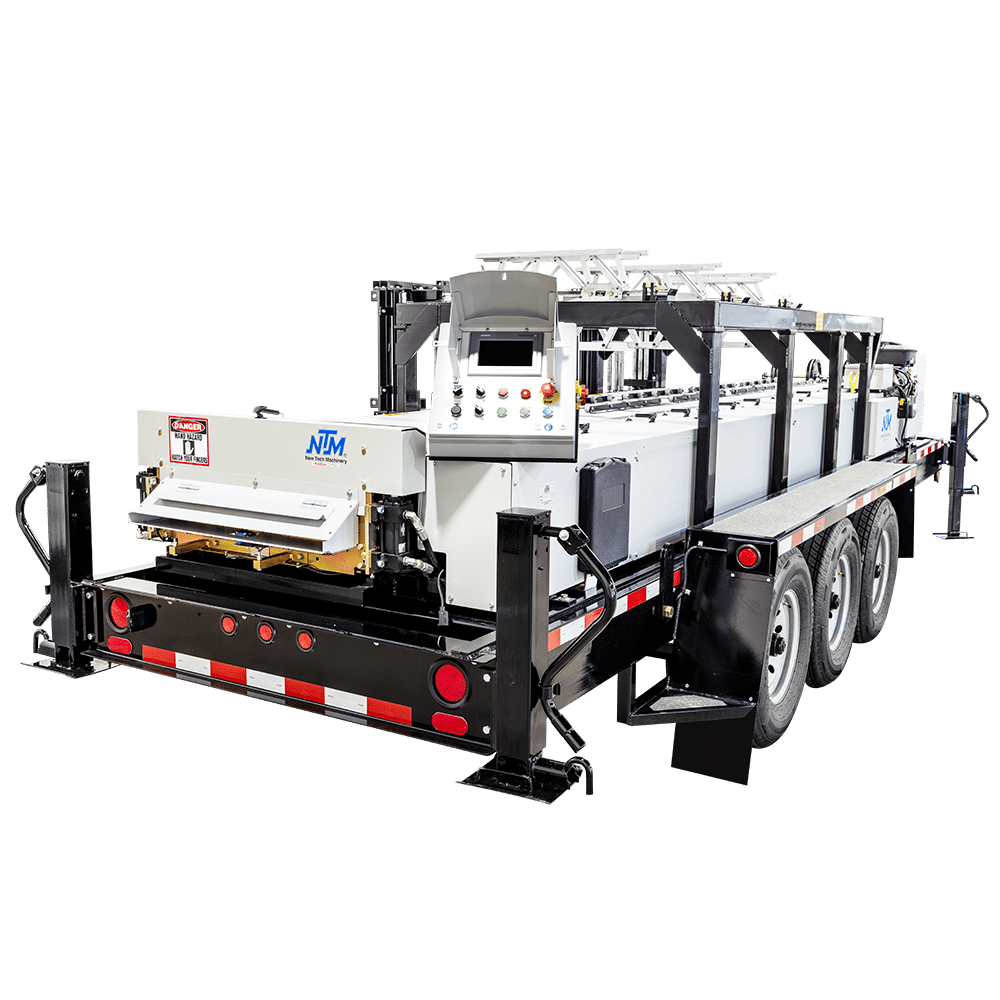

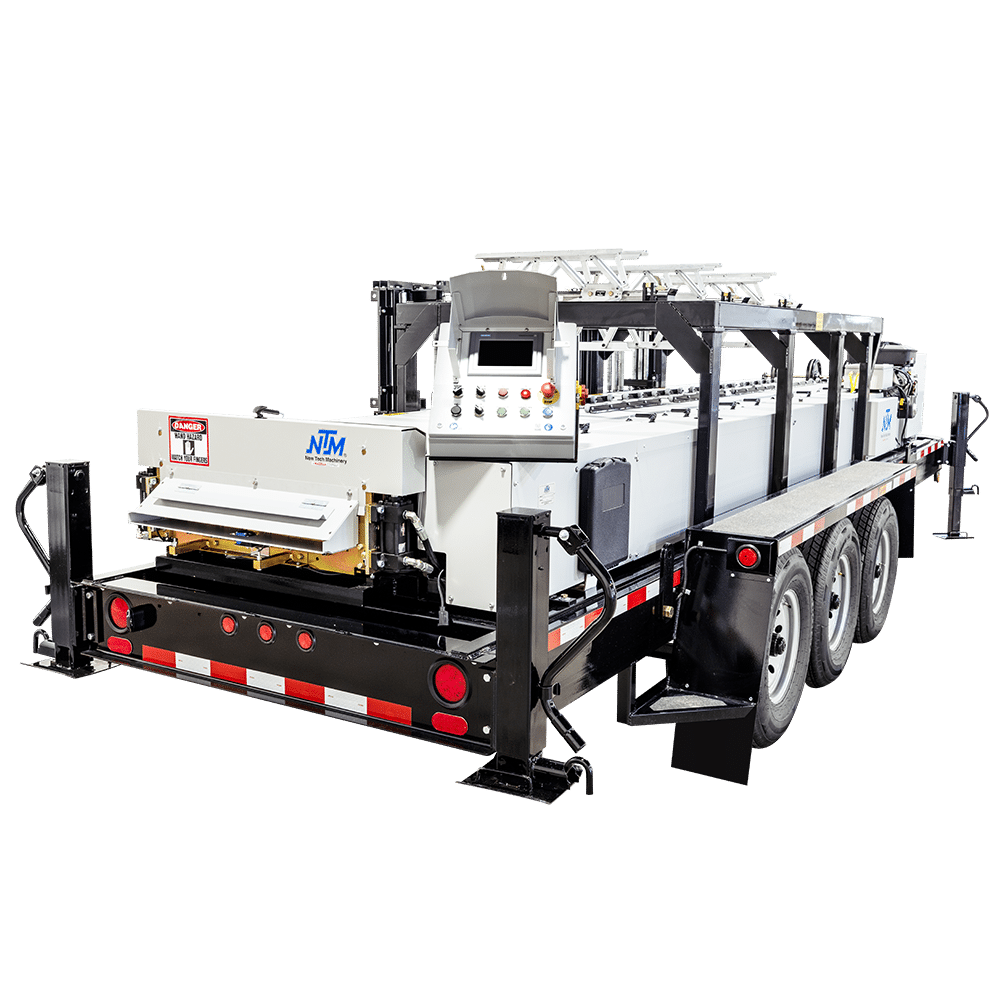

New Tech WAV™ Wall Panel Machine

The WAV™ Wall Panel Machine is a revolutionary solution, standing as the industry's only portable rollformer capable of producing the distinctive WAV-style architectural wall panel. This machine empowers contractors to bring high-end panel production directly to the job site, delivering unparalleled speed, versatility, and quality for commercial and architectural applications. By eliminating the reliance on factory-formed panels, you gain complete control over your project's schedule and budget.

The Industry's Only Portable WAV Profile Machine

The WAV™ Wall Panel Machine is engineered for high-output production and exceptional performance, making it the definitive choice for contractors specializing in architectural metal wall systems. Its ability to produce multiple panel widths from heavy-gauge steel and aluminum on-site transforms your operational efficiency. Featuring the advanced UNIQ™ Automatic Control System and robust hydraulic power, the WAV machine is built to perform in the most demanding environments, ensuring every panel is produced to exact specifications.

Key Features

The WAV machine combines speed, power, and intelligent control to deliver a superior production experience.

- High-Speed Production: Achieves speeds up to 150 feet per minute (45.7 m/min) with electric power, dramatically increasing job site productivity.

- Multi-Width Capability: Produces 16", 12", and 8" wide WAV-style profiles, offering design flexibility for any project.

- Heavy-Gauge Material Forming: Effortlessly forms 22 or 24-gauge Grade 50 steel and .032” to .040” aluminum, perfect for robust architectural designs.

- UNIQ™ Automatic Control System: Provides intuitive, automated control over batch and length production for ultimate precision and minimal waste.

- Dual Power System: Equipped with both a 16 HP gas engine and a 460V 3-phase electric motor for maximum versatility on any job site.

Technical Specifciations

| Feature | Description | |

| Drive System | Hydraulically driven via chain and sprocket, using 24 polyurethane drive rollers. | |

| Shear | Hydraulically powered with hardened tool steel blades and a panel recognition proximity sensor. | |

| Machine Dimensions (L x W) | 22’ 8” (6.7m) x 5’1” (1.5m) | |

| Machine Weight | Approx. 5,000 lbs. (2,273 kg) | |

| Speed | Up to 150 ft/min (Electric); Up to 75 ft/min (Gas) | |

| Materials Formed | 22-24 ga. Painted Steel; .032”-.040” Painted Aluminum (16" profile only) | |

| Panel Coverage | 16” (406mm), 12” (305mm), 8” (203mm) |