Automated Sheet Metal Cutting & Automated Cut to Length Machine

Krasser Optima

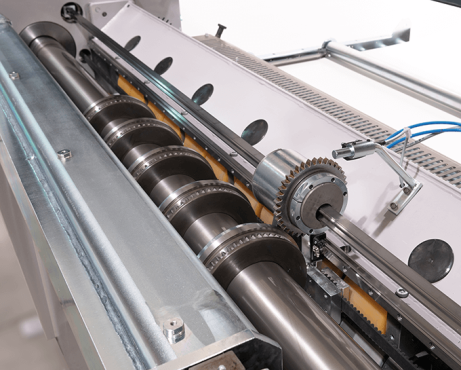

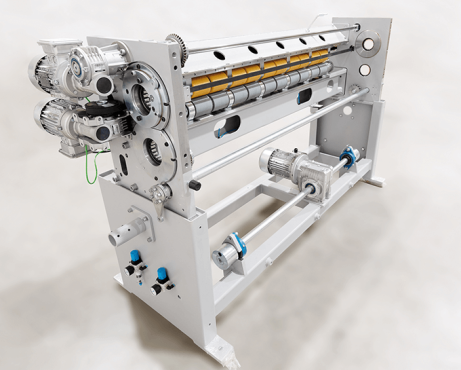

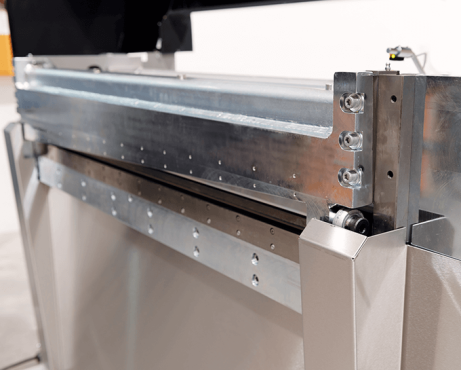

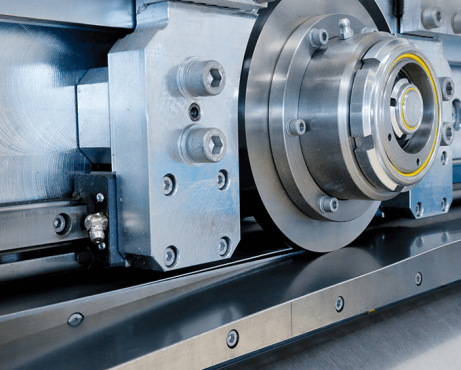

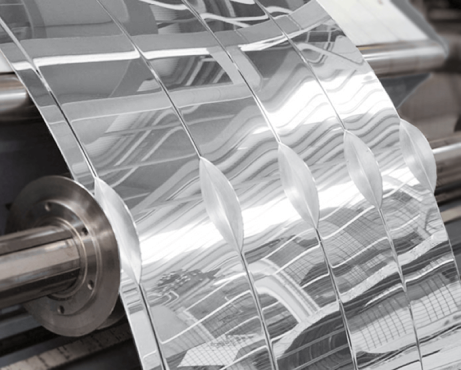

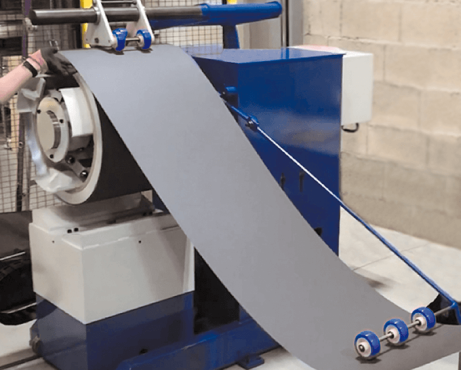

With the OPTIMA automated slit to width and cut to length system, your cutting requirements are completed in record time. Constructed to be reliable, efficient, and robust for continuous operation. The OPTIMA is the most cost-effective automated sheet metal cutting machine on the market, yet still offers numerous features that cover a wide range of applications. Part labeling, small coil processing, recoiling, film application, and straightening are just a few of its features. Its intuitive and user-friendly control has onboard optimization and order management available or can be driven directly by Bendex through its native interface. The fully automatic knife adjustment can position up to 8 pairs of knives, set their gap and plunge. Best cut quality and part accuracy is easily achieved and maintained. Increase your output, reduce you scrap and labor, all with a system optimized to suit your needs.

Benefits

- Robust, reliable, and efficient construction

- Ideal configured software and hardware

- Intuitive and user-friendly operation

- Useful machine control functions

- Lowest priced slitting machine on the market with automatic knife adjustment

- Fully automatic slitting knife positioning (ergonomic, fast, reliable)

- Modular design with several machine system options

- Electronic order management possible