Automated Coil Processing Machine & Solutions

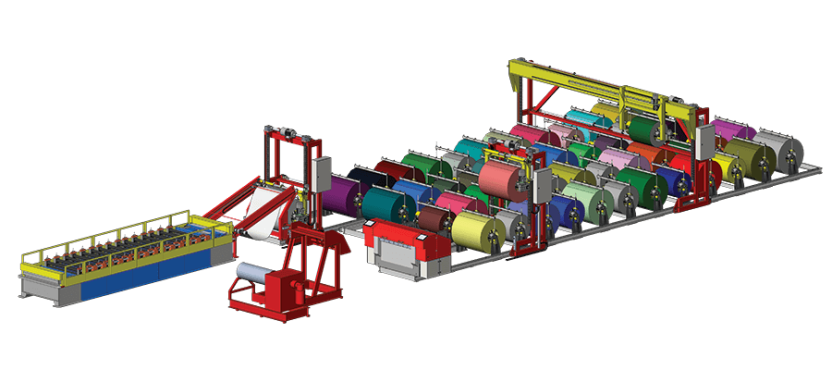

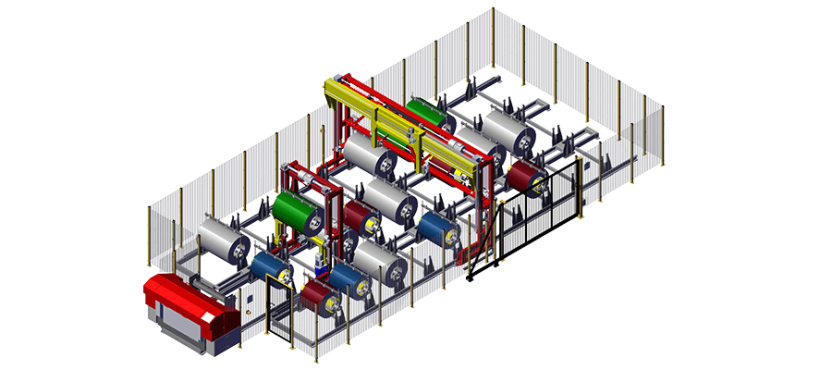

Krasser Centurio Coil Storage and Handling

The Centurio is the world’s most automated coil processing system. For the first time, the entire coil processing operation has been automated–from changing coils to setting knives to simultaneously feeding slitters and rollformers. Push the start button and in less than two minutes coils have been selected and moved into position, knives have been changed and set, machines have started running, pieces have been slit-to-width and cut-to-length and rollforming panels have been produced–all with very little operator involvement and a massive reduction in scrap.

As a stand-alone machine or with an automatic coil storage system, the Krasser Centurio system has been the one to beat in automated coil processing for decades, with continuous innovations. Effortless and safe operation with a high level of production flexibility brings advantages that has been proven time after time.

Benefits

- Designed and built for high production throughput rate (24/7 – production)

- Decrease scrap with accurate cutting

- High production flexibility

- Fully automatic coil exchange

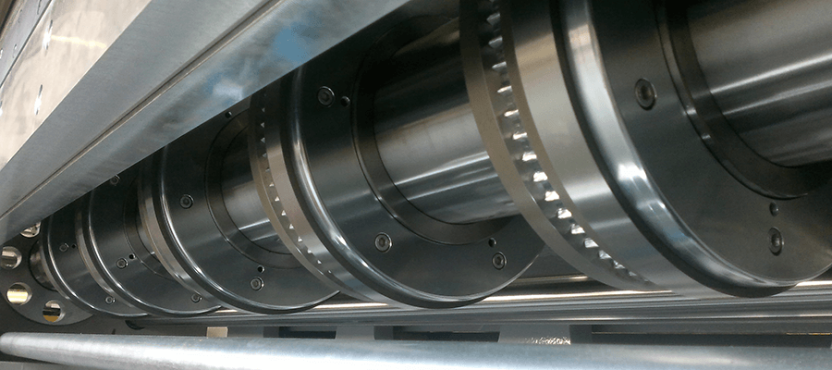

- Fully automatic knife positioning

- Reliable and robust build

- Modular design with several machine system options