Stolarczyk Tension Stand & Recoiler

The Stolarczyk Tension Stand and Recoiler is highly efficient and easy to use. Reduce your cut cost and lead time on custom coil widths. The tensioner clamps the material via pneumatic pressure with felt pads. The pressure gauge is fully adjustable for accurate clamping of material. The loop is controlled utilizing a dancer arm. Shafts with separating disks ensure the material is guided to the tensioner and recoiler. Separating disks are included in the basic price for a total of 6 Slits.

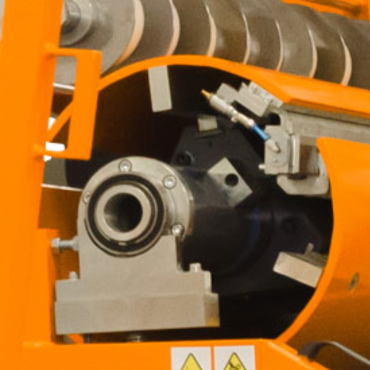

The recoiler is open frame cantilevered design for easy load/unload of coil. Overhead guide with separating disk to ensure alignment of coil. The recoil speed is controlled via dancer arm control but is fully adjustable via a rotary potentiometer. Stolarczyk Tension Stand and Recoiler can be customized to your needs. Some additional options are coil cart for the recoiler, quick change felt, rotary exit shear, pneumatic clamp for recoiler, and in feed lifting table.

Benefits

- Advanced recoiling systems for today’s needs

- Highly capable solution for coil processing

- Pneumatic lifting table for single person operation

- Coil cart for easy removal of finished coils

- Measured length for small coils without removing the complete master coil

- Quality construction for long life span

- Standard 2 year warranty

| Recoiling System with Cut Off Shear and Lifting Table | |||||||

| Capacity | Mandrel clamping range | Mandrel Expansion | Recoil Speed | Power with frequency inverter | Width of Coil | Minimum Strip Width to Recoil | Maximum Diameter of Coil |

| 11,000 lb. | 18.9” x 20” | Hydraulic | 115 ft/min | 14 KW | 49.2” | 6” | 51.2” |