MetalForming Offers

New Tech Rollformers

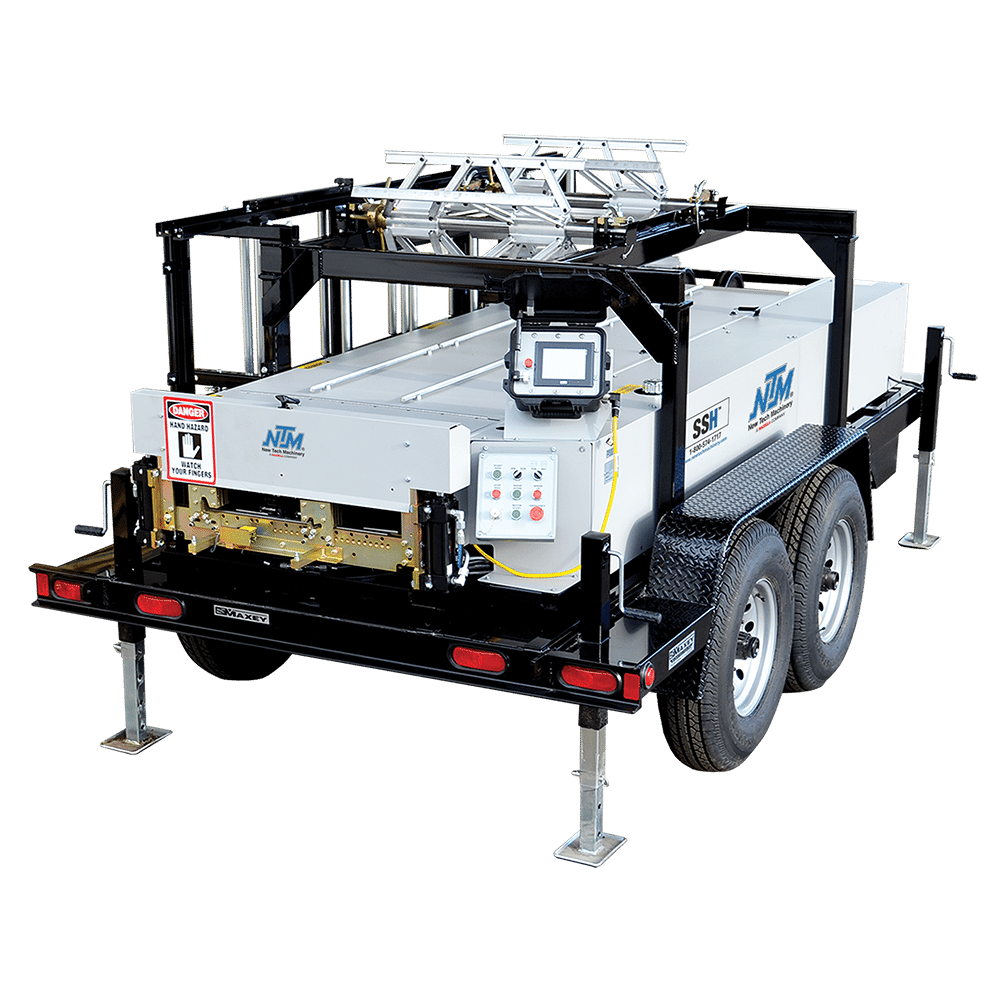

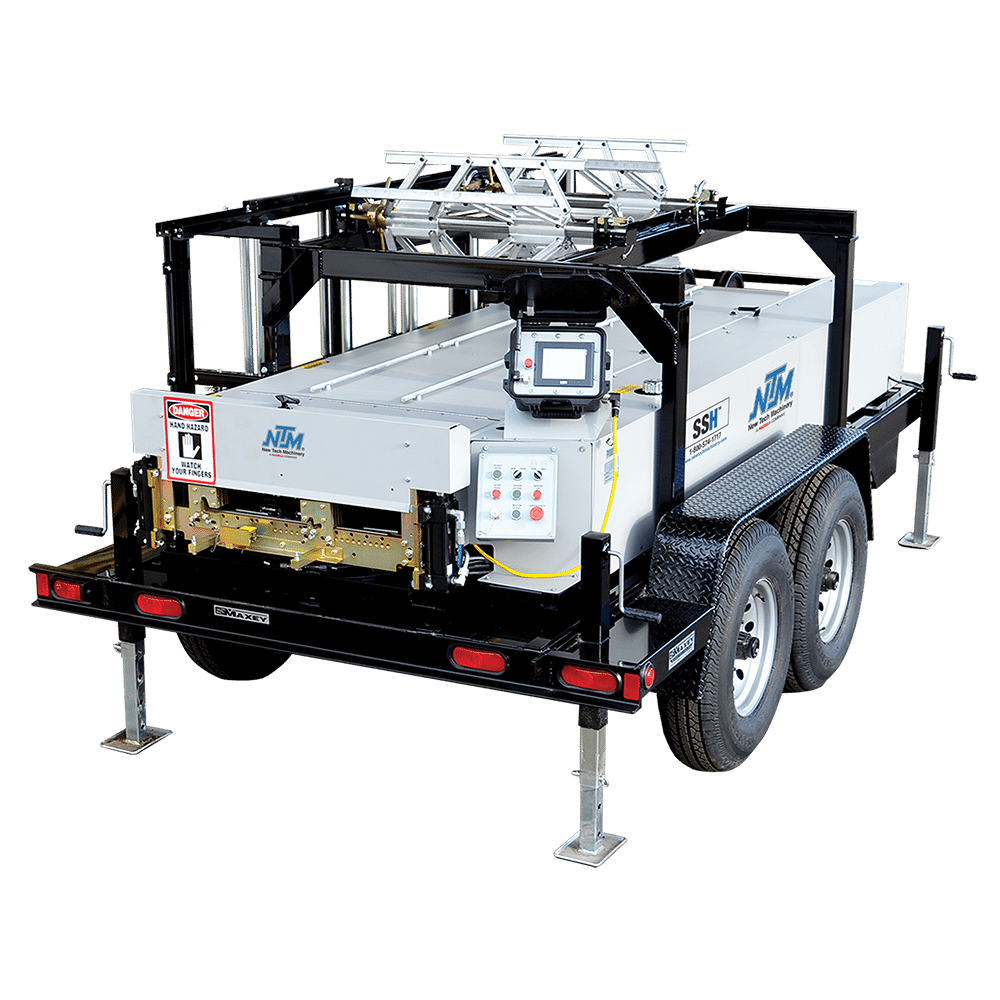

New Tech SSH™ MultiPro Roof Panel Machine

For residential and light commercial projects, the SSH™ MultiPro delivers portable, high-precision rollforming with every job. Its robust design, ease of use, and rapid profile change capabilities help reduce lead times, lower costs, and minimize material waste—making it the go-to choice for professionals who demand more from their machinery.

A Portable Solution for Modern Metal Roofing

The SSH™ MultiPro Roof Panel Machine stands out as the ultimate on-site rollformer for premium standing seam metal panels. With seven exchangeable profiles and the ability to process various metals and coil sizes, this machine adapts to diverse architectural needs without hassle. A reliable hydraulic drive and shear, intuitive computerized controls, and both gas or electric power choices ensure it’s ready for any job—every day.

Key Features

- 7-Profile Capability: Change quickly between snap-lock, mechanical seam, and T-panel profiles.

- Material Versatility: Handles painted steel (28–24 ga.), aluminum (.027"–.040") & copper (16–20 oz.).

- On-Site Production: Create finished panel widths from 12" to 20" using coils between 14"–24".

- Fast Operation: Up to 60 ft/min output for maximum productivity.

- Hydraulic Drive & Shear: Reliable, consistent performance plus clean, accurate cuts.

- Easy Controls: PLC computerized controller for batch and length programming.

- Quick-Change Power Pack: Select gas or electric power suiting any environment.

- Safety First: Power Interruption Safety Circuit built in for operator security.

- UL Panel Capability: Produce UL-rated panels—confirm certification for specific applications.

Technical Specifications

| Feature | Description |

| Machine Length | 12′ 10” (3.9 m) |

| Machine Width | 4′ 10-1/2″ (1.2 m) |

| Height (with rack) | 4' 3" (1.3 m) |

| Weight (Base Machine) | 2,360 lbs. (1,070 kg) |

| Maximum Speed | ≈ 60 ft/min (18.3 m/min) |

| Coil Width Range | 14”–24” (355–610 mm) |

| Finished Panel Width | 12”–20” (254–508 mm) |