Folding technology solves what press brakes can't

Rethinking Fabrication: Precision Folding for Today’s Challenges

The ongoing labor shortage is exposing a fundamental reality—conventional bending techniques are no longer sustainable for modern fabrication demands. As the most complex and influential stage in the production process, bending directly impacts the efficiency, quality, and cost of every operation that follows.

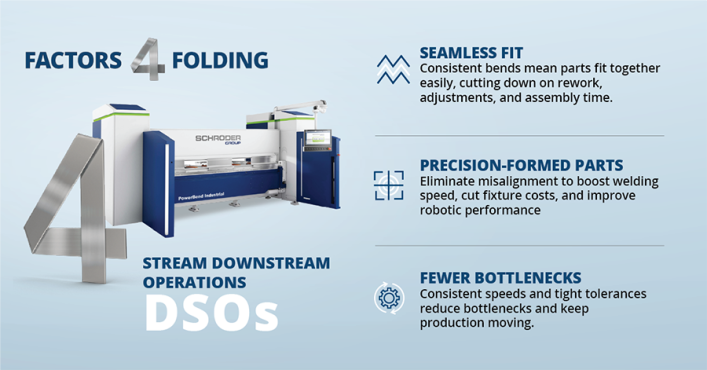

Precision folding technology is transforming the way shops operate. It offers a smarter, more consistent approach to bending that:

- Minimizes labor requirements

- Solves material handling bottlenecks

- Ensures repeatable part accuracy

- Reduces downstream production costs

Seamlessly integrating into existing workflows, precision folding systems deliver efficient, high-quality output from day one, offering a rapid return on investment. By applying core lean principles, eliminate, reduce, and simplify—folders dramatically cut labor demands by resolving material handling challenges and consistently producing parts that exceed print tolerances. This eliminates costly rework and bottlenecks in downstream operations. Equally effective in high-mix/low-volume and high-volume/low-mix environments, folding ensures consistent cycle times and part quality, regardless of part size or operator experience. It’s a future-proof solution that protects your operation from labor shortages, rising costs, and shifting market demands.

If you’re serious about improving efficiency, precision, and labor control, it’s time to stop managing around the problem—and start eliminating it. Modern demands require more than marginal improvements. They require a fundamental shift. Folding delivers it.

Meet the Expert

With nearly four decades of experience in leading-edge fabrication technologies, David Prokop has built a reputation as a trusted expert in the field. After earning a degree in Industrial Engineering, he began his career as a technician for an import company, helping manufacturers across North America implement the latest press brake innovations from Europe — including machines from Beyeler, Donewell, Warcom, and Weinbrenner.

Frustrated by the frequent misrepresentation of technology in the sales process and the resulting challenges during training, David transitioned into sales to bridge the gap between technical expertise and customer expectations. A turning point came after discovering folding technology at a European machine tool show almost 30 years ago, a moment that sparked a lifelong passion and sharp focus on this transformative approach to metal forming. Over 20 years ago, David began importing Schroeder folding machines, becoming one of the earliest and most consistent champions of the technology in the North American market. Today, he continues to serve as a expert resource for companies seeking precision, efficiency, and innovation in their fabrication operations.