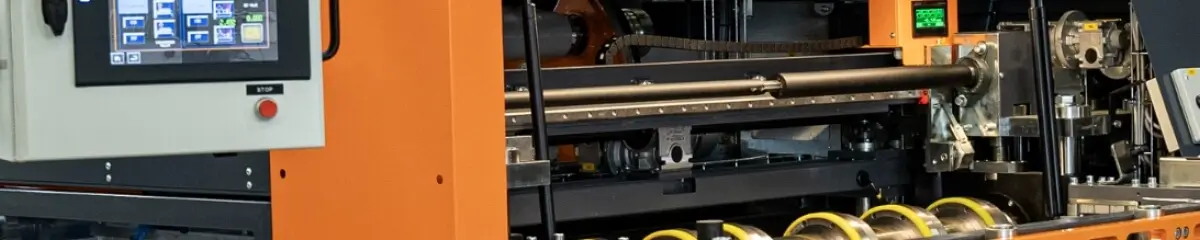

Coil Processing Equipment

Manufacturers who rely on accurate, repeatable metal preparation choose coil processing equipment that supports consistent output and dependable workflow efficiency. Our systems are engineered to help precision fabrication shops manage coil stock with the control, productivity, and reliability needed to maintain tight tolerances and keep production moving.

See Our Coil Processing Selection

Every great project begins with dependable equipment. Not sure which machine fits your needs? Our team is always ready to help.

Complete Coil Processing Machinery for Demanding Operations

Our selection of coil processing machinery is built for teams that expect stable performance from every stage of their material-handling workflow. Each machine is selected for its durability, ease of use, and seamless integration into forming equipment and downstream fabrication processes. These systems support continuous operations and give you the accuracy required for high-volume or high-precision production.

MetalForming sources equipment from global leaders such as Stolarczyk and Schlebach, and services Krasser, offering performance-driven solutions backed by US-based service, parts, and technical expertise.

Stolarczyk equipment forms the foundation of our coil processing systems, and is trusted for its dependable performance and practical, high-quality design. These machines deliver the reliability needed to keep production on schedule.

Whether you’re upgrading a single workstation or planning a complete material-handling line, you’ll find equipment engineered for long-term stability and measurable ROI.

Types of Coil Processing Equipment We Offer

Our lineup encompasses the entire coil-handling and preparation process, providing shops with the necessary tools to enhance throughput, improve accuracy, and reduce operator strain.

Decoilers

Decoilers unwind coil stock smoothly and maintain controlled tension to prevent material distortion. Ideal for precision metal forming environments that require predictable feed rates and consistent downstream performance.

Slitters/Cutters

Slitters and cutters reduce coils to clean, accurate widths that support architectural, OEM, and precision-fabrication applications. These machines are engineered for straight, uniform cuts at production-level speeds.

Recoilers

Recoilers wind processed material into stable, manageable coils that support staged workflows, storage, and transport. Their construction ensures balanced winding that preserves material integrity.

Stacking Tables

Stacking tables organize cut pieces with the stability required for high-volume part flow. These tables streamline operator movement, simplify sorting, and help maintain smooth transitions between cutting and forming operations.

Coil Handling Systems

For shops handling larger volumes or wider coil ranges, our coil handling systems deliver the automation, consistency, and safety needed for continuous production. These solutions are configurable to match your exact workflow and performance requirements.

Why Precision Manufacturers Choose MetalForming

Reliable Performance

Every machine is selected for long-term durability and predictable operation under heavy use. Our brands are trusted worldwide for clean engineering and dependable performance.

Designed for Accuracy

Precision manufacturers depend on consistent coil preparation. Our equipment minimizes variability, protects material surfaces, and helps maintain tight tolerances throughout forming and finishing processes.

Integrated Support

A system is only as strong as the service behind it. MetalForming provides installation, training, parts, and ongoing technical support to ensure your equipment stays productive.

Smart Investment Value

We offer steel coil processing equipment and coil handling equipment that balance advanced performance with practical ownership costs. The result: faster workflows, reduced waste, and improved production quality.

Proven Global Partnerships

Our brands bring decades of engineering experience and innovation to North American shops. This gives you access to the best European technology supported by a US-based team.

Ideal for High-Precision and High-Volume Production

Our coil processing solutions support a wide range of applications, including:

OEM suppliers

Metal service centers

Architectural sheet-metal fabricators

Automotive and appliance production

Contract manufacturing

Facilities that rely on forming equipment for continuous throughput

If your operation requires consistent material flow, accurate coil preparation, and dependable uptime, these systems are engineered for your environment.

Talk to a Coil Processing Equipment Specialist

Contact UsChoosing the right coil processing setup can transform your productivity and material flow. Our team helps you evaluate equipment options, design efficient systems, and align technology with your shop’s workload and long-term goals.

Start your project with experts who understand precision manufacturing. Contact us to request a quote or schedule a consultation today.

FAQs About Coil Processing Equipment

Coil processing equipment prepares coiled metal for fabrication by unwinding, cutting, rewinding, and organizing material. It includes:

Decoilers that unwind coiled material

Slitter/cutters that cut coils into usable widths

Stacking tables that organize cut pieces

Recoilers that wind processed material back into manageable coils

Manufacturers who purchase material in coil form and need an efficient preparation process. Common users include metal service centers, appliance producers, automotive suppliers, architectural fabricators, and precision forming operations.

We offer coil processing machinery including slitters/cutters, decoilers, recoilers, stacking tables, and full coil handling systems. Each solution is selected for production stability, simplified maintenance, and long-term value.