Architectural Sheet Metal Forming Machines

Contact Us TodayMetalForming LLC supplies specialized sheet metal machinery for architectural projects, including solutions for roofing systems, exterior panels, and precision fabrication. Our equipment is designed to support contractors, manufacturers, and fabricators. Find a metal forming machine capable of accurately and efficiently meeting your architectural needs for folding, coil processing, and roll forming.

The Role of Architecture Sheet Metal Machines in Modern Design

MetalForming LLC supplies the machinery used to bend, cut, and shape sheet metal into components for structural and aesthetic purposes. In architecture, this includes panels, trim, flashing, and complete roofing systems. These machines are critical to production workflows where accuracy and material durability are crucial.

In construction, roofing systems must meet strict standards for performance, longevity, and appearance. Architectural sheet metal machines allow the manufacture of roofing components that meet project specifications and withstand environmental exposure.

As demand increases for metal-based design solutions in commercial and residential buildings, architectural forming equipment plays a direct role in maintaining build quality and construction efficiency.

Metal Forming Solutions for the Architectural Industry

MetalForming LLC distributes architectural sheet metal machines engineered to handle the full metal forming process, starting with unshaped metals and ending in fabricated roofing, siding, and other components.

We’ve designed these solutions specifically for the needs of architectural contractors and construction professionals. Our product portfolio includes all of the following:

Rollformers: Create consistent cross-sections for panels and cladding through continuous bending.

Curving & Standing Seam Metal Roofing: Shape metal for both design and structural compatibility, allowing precise curved profiles for custom builds.

Metal Folders: MetalForming is the largest distributor of these in North America, providing machines used to bend panels into final shapes for roofing and architectural components.

Shears: Execute clean, straight cuts to exact dimensions, essential in high-volume panel production.

Metal Handbrakes: Create metal shapes ready for architectural use with reliable handbrake equipment.

Coil Processing: Manage and prepare metal coils for fabrication through decoiling, slitting, and cut-to-length operations.

Software: Advanced Software solutions for the sheet metal industry.

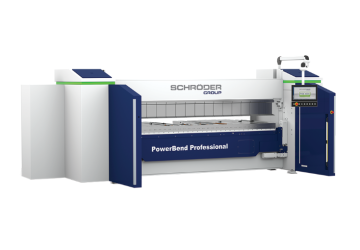

Featured Architectural Sheet Metal Machines for Professional Use

MetalForming LLC carries a selection of high-performing machines that professionals use in architectural sheet metal fabrication. We’ve selected each model for its reliability and production speed, always meeting the tight specifications of roofing and cladding work.

Each machine plays a distinct role in architectural fabrication and has been selected for its compatibility with professional production environments, material specifications, and project needs.

Why Choose MetalForming for Architectural Metal Machinery Solutions?

When you turn to MetalForming LLC, you invest in more than just high-performance equipment. With decades of experience in architectural metal fabrication, our company offers reliable tools, technical expertise, and ongoing support through every step of the process.

These key advantages show why MetalForming remains a trusted supplier for architectural metal machinery.

Full-Service Expertise in Architectural Roofing Machinery

MetalForming delivers machines along with the training, installation, and consulting services needed to operate them effectively. Our expert team supports every stage of implementation, from equipment selection to process optimization.

This full-service approach allows roofing fabricators to reduce downtime, improve efficiency, and meet performance goals without relying on multiple vendors or outside consultants.

Our team regularly collaborates with key roofing industry professionals and works to help roofing contractors become more efficient. Contact us to learn more about our roofing machinery expertise today.

Commitment to Quality and Craftsmanship

With thousands of machines in use across North America, MetalForming’s portfolio of architecture sheet metal machines demonstrates durability, precision, and operational consistency.

With a focus on material integrity and clean finish standards, our equipment helps builders and manufacturers meet performance goals while maintaining the visual expectations of architectural construction.

Industry Affiliations & Roofing Certifications

MetalForming is a recognized name within the architectural metal fabrication industry. Our company holds active memberships in trade associations that support professional standards and continuing education in metal construction.

These affiliations and certifications include the following:

- Metal Construction Association

- National Roofing Contractors Association

- Colorado Roofing Association

- Florida Roofing and Sheet Metal Contractors Association

- Roofing Contractors Association of Texas

- Western States Roofing Contractors Association

- Midwest Roofing Contractors Association

MetalForming also maintains a presence at key events such as METALCON and the International Roofing Expo, reinforcing our authority in the architectural roofing machinery market.

Elevate Your Projects with MetalForming’s Architectural Sheet Metal Machines

MetalForming LLC provides the tools and expertise needed to produce high-quality components with precision and efficiency. If your work involves architectural sheet metal machines, roofing machinery, or any specialized metal fabrication, MetalForming delivers machines that meet industry demands and production goals.

Our architectural metal machinery solutions offer long-term value supported by training, services, and expert consultation for contractors, fabricators, and builders looking to improve output and reduce downtime.

Contact MetalForming today to discuss equipment options and get a quote for your next architectural fabrication project.