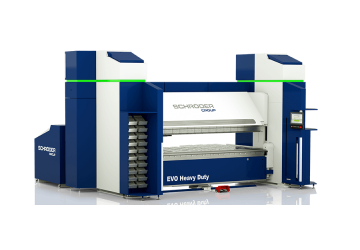

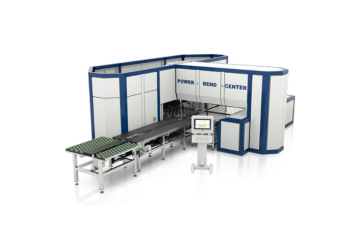

Schroeder EVO Center

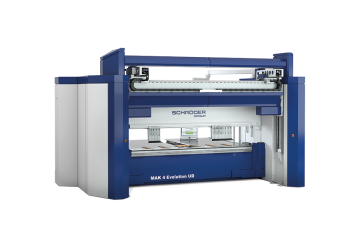

The highly automated EVO-CENTER with ATC (Automatic Tool Change) gives you complete control over your bending needs. A single set of 15-3/4” tools that are automatically changed drastically reduces setup times while increasing the flexibility and part potential. Eliminate part flipping, part whip, and multiple operators with bi-directional folding and ergonomic automation. Since material variance has virtually no impact on part accuracies, you get parts with superior quality, and automated operation removes operator influence over part quality, and output.

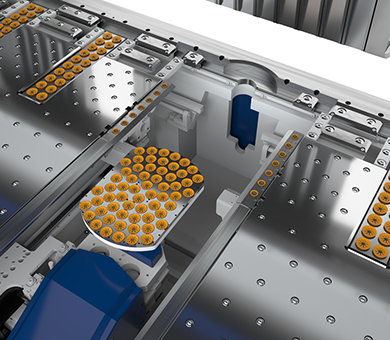

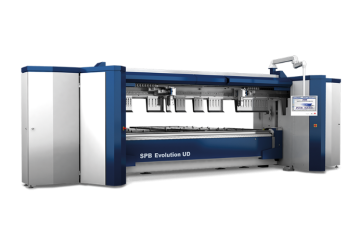

Schroeder Advanced Handling System (AHS) is a further development of the well-known suction gauge and offers the highest level of automation that can be achieved on a folding machine without the use of a robot. AHS can rotate – this means that the sheet gets turned to process the next bending side. Two camera systems control the process – pictures from the workpiece are compared with the CAD-data. Light barriers around the machine provide safety on the rear side of the machine.

Through the combination of the Up-and-Down folding beam, the suction gauge and the rotating plate with suction cups in the center of the machine the software control is able to program the whole bending program without any manual intervention. The EVO Center is your industrial solution to achieve large-volume as well as flexible series production with utmost repeat accuracy.

Benefits

- Semi-automatic up and down folding

- Fully-automatic tool change (ATC)

- Highest level of automation on a folding machine without using a robot

- Movable display via guide rail

- Easy to use software with touchscreen control

- Two independently controlled and movable tables

- Automatic alignment with rotating plate

| EVO-CENTER | 3200 X 4.0 | 4000 X 3.0 |

| Working length | 3240 mm (127 in) | 4040 mm (159 in) |

| Sheet thickness (400 N/mm2) | 4.0 mm (9 ga) | 3.0 mm (11 ga) |

| Machine length | 9406 mm (30 ft - 10 in) | 10206 mm (33 ft - 5 in) |

| Weight | 18,100 kg (39,900 lbs) | 21,280 kg (46,910 lbs) |

| CLAMPING BEAM | |

| Geometry | 180° |

| Stroke | 850 mm (33 in) |

| Drive power | 2 x 6.69 kW |

| Speed | 120 mm/s (285 ipm) |

| FOLDING BEAM | |

| Adjustment | 200 mm (7.87 in) |

| Drive power | 2 x 7.0 kW |

| Speed | 150°/s |

| Bending center adjustment | 80 mm (3.15 in) |